Foundation Shortcuts That Cause Major Problems

The foundation is literally what everything else stands on, but it’s where many builders try to save money in ways that homeowners never see. Recent construction industry reports from 2024 show that nearly 23% of foundation failures stem from inadequate excavation depth or poor soil preparation. Builders sometimes skip proper soil testing, which can cost around $1,200, and instead guess at soil conditions. They might also use cheaper concrete mixes or reduce the amount of rebar reinforcement, cutting material costs by 15-20% but potentially compromising structural integrity for decades. When foundation problems emerge years later, repairs can cost homeowners between $15,000 and $30,000. The National Association of Home Builders documented in their 2024 survey that foundation-related callbacks are among the most expensive warranty claims builders face.

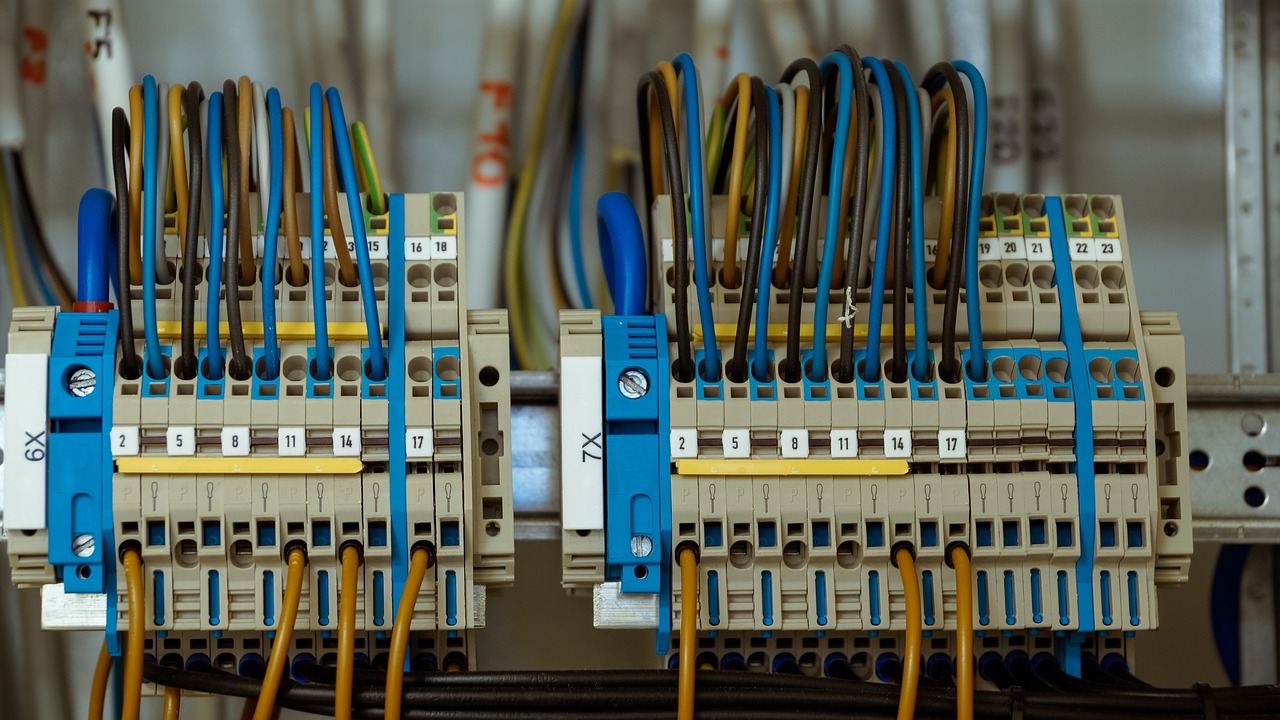

Electrical Work That Meets Minimum Code Requirements

Electrical systems often get the bare minimum treatment because most homeowners can’t see what’s behind the walls. According to the National Fire Protection Association’s 2024 report, homes built with minimal electrical planning account for 35% more service calls within the first five years. Builders frequently install just enough outlets to pass inspection, leaving homeowners scrambling for extension cords later. They might also use the cheapest acceptable wire gauge, install basic circuit breakers instead of AFCI or GFCI protection where not absolutely required, and skip whole-house surge protection. Modern homes need significantly more electrical capacity than code minimums, especially with electric vehicle charging and smart home devices becoming standard. The average cost to upgrade electrical systems after construction is three times more expensive than doing it right initially.

HVAC System Sizing and Ductwork Disasters

Heating and cooling systems get sized based on quick calculations rather than proper load analysis, leading to inefficient and uncomfortable homes. The Air Conditioning Contractors of America reported in 2024 that over 60% of new residential HVAC systems are improperly sized, with most being oversized. Builders choose oversized units because they’re often cheaper per ton and seem like they’ll keep homes more comfortable. However, oversized systems cycle on and off frequently, never properly dehumidifying air and wearing out components faster. Ductwork often gets treated as an afterthought, stuffed into whatever space is available with sharp bends and inadequate return air paths. Studies from Lawrence Berkeley National Laboratory show that typical residential duct systems lose 20-30% of conditioned air through leaks and poor design.

Insulation Gaps and Thermal Bridging Issues

Insulation installation looks simple but requires attention to detail that many builders skip to save time and labor costs. Building science research from 2024 indicates that improper insulation installation can reduce a home’s energy efficiency by up to 50%, even when using high-quality materials. Common shortcuts include compressing batts into cavities, leaving gaps around electrical boxes and pipes, and failing to air-seal before insulating. Thermal bridging through studs and headers often gets ignored because adding continuous exterior insulation increases material costs by roughly $3-5 per square foot. Many builders also skip detailed blower door testing, which costs around $300-500 but can identify air leakage that dramatically impacts comfort and energy bills. The Department of Energy’s 2024 building performance studies show that homes with properly installed insulation and air sealing use 30-50% less energy than code-minimum construction.

Windows and Door Installation Shortcuts

Window and door installation involves crucial waterproofing steps that builders sometimes rush or skip entirely. The Window and Door Manufacturers Association documented in their 2024 quality report that improper installation causes 85% of window-related failures within ten years. Builders might skip proper flashing tape, use inadequate sealants, or fail to slope sills correctly for drainage. These shortcuts can save 30-45 minutes per opening and reduce material costs by $20-40 per window, but they create pathways for water infiltration that can cause thousands in damage. Door installation often suffers from similar issues, with builders skipping proper shimming and weather sealing to speed up the process. Professional installation guidelines require specific sequences and materials, but many crews develop faster methods that meet visual inspection requirements while compromising long-term performance.

Roofing Material and Installation Compromises

Roofing represents a significant material cost, so builders often look for ways to reduce expenses without obvious visual impact. Industry data from 2024 shows that 40% of premature roof failures result from installation shortcuts rather than material defects. Common cost-cutting measures include using minimum nail patterns, skipping ice and water shield in areas beyond code requirements, and reducing underlayment quality. Builders might also space roof trusses at maximum allowable distances, use minimum sheathing thickness, or install cheaper ventilation systems. These decisions can reduce roofing costs by 15-25% but may lead to problems during severe weather events. The National Roofing Contractors Association reports that properly installed roofing systems last 40-60% longer than those installed with cost-cutting shortcuts.

Plumbing Pipe Materials and Layout Efficiency

Plumbing systems get designed for minimum cost and maximum installation speed rather than long-term performance and maintenance access. Recent plumbing industry surveys from 2024 reveal that builders increasingly use plastic pipes and fittings throughout homes, even in applications where copper or other materials would perform better long-term. They often design plumbing runs for material efficiency rather than service access, burying pipes in walls and slabs where future repairs become expensive and disruptive. Water pressure and flow calculations sometimes get skipped, leading to inadequate performance in fixtures farthest from the main line. Builders also frequently eliminate water hammer arrestors, whole-house water filtration rough-ins, and convenient shutoff valves to reduce costs by $800-1,200 per home. These shortcuts create maintenance headaches and limit future upgrade options for homeowners.

Interior Finish Work and Hardware Quality

Interior finishes offer numerous opportunities for builders to cut costs while maintaining visual appeal during initial home tours. Paint preparation often gets rushed, with builders skipping proper priming, hole filling, and surface sanding that ensure long-lasting results. Cabinet hardware, door handles, and plumbing fixtures typically get downgraded to the cheapest acceptable options, even though upgrading would cost relatively little during construction. Flooring installation frequently involves shortcuts like inadequate subfloor preparation, minimal expansion gaps, or reduced underlayment quality. The National Association of the Remodeling Industry’s 2024 study found that interior finish shortcuts account for 70% of buyer complaints within the first two years of home ownership. These issues rarely affect structural integrity but significantly impact daily living satisfaction and resale value.

Structural Lumber Grade and Fastener Selection

Lumber grading and fastener selection might seem technical, but these choices significantly impact long-term structural performance. Construction material studies from 2024 show that builders increasingly specify minimum grade lumber and standard fasteners even in applications where upgrades would provide substantial benefits. Engineered lumber products often get substituted with dimensional lumber to reduce costs, even though engineered options provide more consistent performance. Fastener specifications frequently get downgraded from structural screws to standard nails, or from galvanized to plain steel in applications where corrosion resistance matters. These material substitutions can reduce framing costs by 8-12% but may create serviceability issues decades later. The Structural Building Components Association reports that proper material selection and fastening increases building performance and longevity significantly compared to minimum code compliance.

Site Drainage and Landscaping Preparation

Site drainage work happens mostly underground and gets little attention from buyers, making it an attractive area for cost reduction. Civil engineering data from 2024 indicates that improper site drainage causes more long-term foundation and basement problems than any other single factor. Builders often reduce excavation depth for drainage systems, use smaller diameter pipes than optimal, or eliminate redundant drainage paths to save on material and labor costs. Soil grading around homes frequently gets rushed, creating subtle slopes toward foundations rather than away from them. French drains, curtain drains, and other water management systems might get eliminated or reduced in scope to cut costs by $2,000-5,000 per home. The American Society of Civil Engineers notes that proper site drainage prevents 80% of moisture-related structural problems but adds relatively little to construction costs when planned properly.

Quality Control and Final Inspection Processes

Quality control represents an ongoing cost throughout construction that builders sometimes reduce by limiting inspection frequency and detail. Construction industry analysis from 2024 reveals that homes receiving comprehensive quality control inspections have 60% fewer callback issues and warranty claims. Builders might reduce third-party inspections beyond those required by code, skip detailed punch list processes, or assign quality control responsibilities to trade contractors rather than independent inspectors. Pre-drywall inspections often get rushed because scheduling pressure mounts as construction progresses, and problems become expensive to fix after walls are closed up. Final walk-throughs with buyers sometimes focus on cosmetic issues while overlooking functional problems that will emerge over time. The National Association of Home Builders estimates that thorough quality control processes add 1-2% to construction costs but reduce warranty expenses by 40-50% over the first five years of home ownership.

Did you expect that these corner-cutting practices were so widespread across the industry?

A visionary in modern design, Nate Berkman is known for his ability to blend timeless elegance with personal storytelling. With years of experience in high-end interiors, his book Living with Style explores how to create meaningful spaces that reflect individuality.